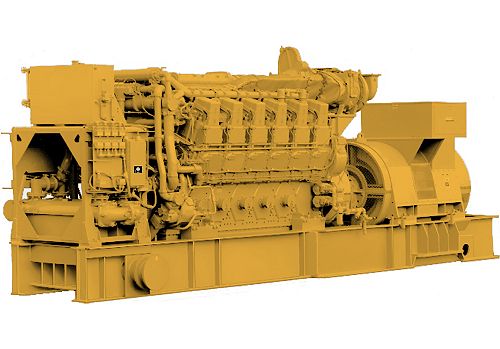

3612 (60 Hz)

- Bore

- 11 in / 280 mm

- Stroke

- 11.8 in / 300 mm

- Displacement

- 13524 in³ / 222 l

Producing reliable power from 3300 to 4000 ekW at 60 Hz, our 3612 diesel generator sets are made to meet your mission critical, continuous, standby and prime applications. We've designed each to ISO 8528-5 transient response requirements and to accept 100% rated load in one step. The generator set is certified for low fuel consumption.